Futureproofing homes has never been more important and it is why fabric measures built-in for the life of a building is one of the most effective ways to reduce energy consumption. While there are a number of design options available to boost efficiency, few offer the impact and cost efficiency of Keystone’s award winning Hi-therm+ Lintel.

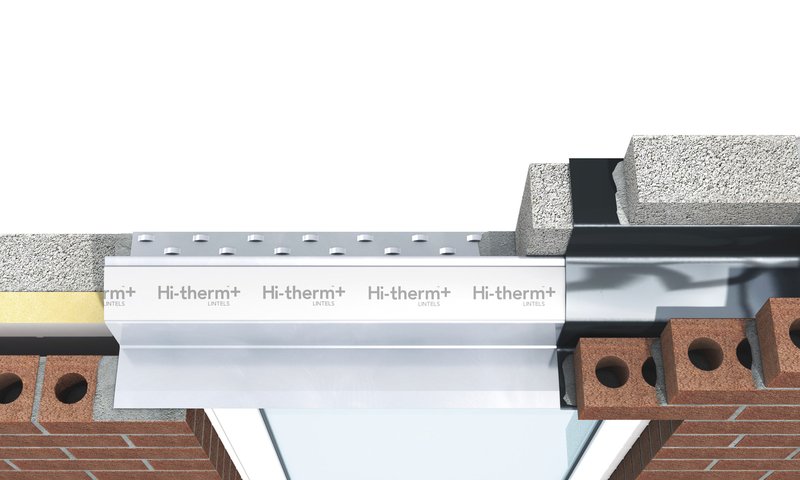

Today almost all lintels in domestic scale dwellings are made from steel for a number of reasons, such as providing more design flexibility and easier onsite handling than other alternatives. However, steel has a high conductivity value and with lintels typically spanning across long lengths when you add them all up in a building, it’s no surprise they are considered one of the most significant contributors to heat loss via thermal bridging. Therefore, considering the thermal performance of lintels at design and specification stage is more important than ever.

Hi-therm+ has set a new standard for thermal efficiency in steel lintels. It incorporates a thermal break and is up to five times more thermally efficient than a standard lintel. Hi-therm+ is a very cost-effective solution, particularly if we look beyond the unit price, as getting the fabric right will save energy throughout the entire life span of the house.

When compared to more costly renewable technologies, which have a limited lifespan and risk a significant increase in CO2 emissions once they reach end of life, fabric-first is the secret to improving thermally-efficient building envelopes.

A new webinar series this autumn, Keystone Live, is exploring key themes from various industry standpoints. The series covers a range of topics and issues including the delivery of net zero housing, offsite construction, designing with non-combustible materials and how the industry is tackling climate change.

For more information or to book your free place on these webinars visit Keystone Live

https://keystonelintels.com/hi-therm-lintels/